Techflow Enterprises Pvt Ltd is one of the prominent and entrusted dealers of Air pollution control devices or products like Dust Collector, Pulse Jet Cartridge Filter, Silo Vent filters, Air pollution control equipment, Dust Recovery systems, Fabric Filter, Off line cleaning bag filter, Online cleaning bag filter, Pulse jet bag filter, bag filter, Reverse air cleaned bag filter, Pulse jet, De-dusting system, Flue gas emission control system, Baghouse, Cassette type filter, Centrifugal fans and blowers, Furnace fume extraction system, Electrostatic precipitator (ESP), Welding fume extraction system and Pneumatic conveying system in India with universal exports.

Techflow has been one of the largest manufacturers of Dust collectors for ball mill since 1980. The inspiration behind designing the Cartridge Type Filter and Dust collector for ball mill was to reduce and ease the spacing and accomplish better equivalence to the Hose type bag filter. Dust collector for ball mill is operated in mid-range temperature applications wherein dust granules are floating freely. Various de-dusting filtration mediums and Dust collectors are available depending upon the needs. In this system, time-defined pulses or concise air flows in the contrasting direction of the primary airflow. Now by momentary reversal via cleaning blast through ventury, the cartridge surface is cleaned.

Discover more| Dust collector for ball mill |

|---|

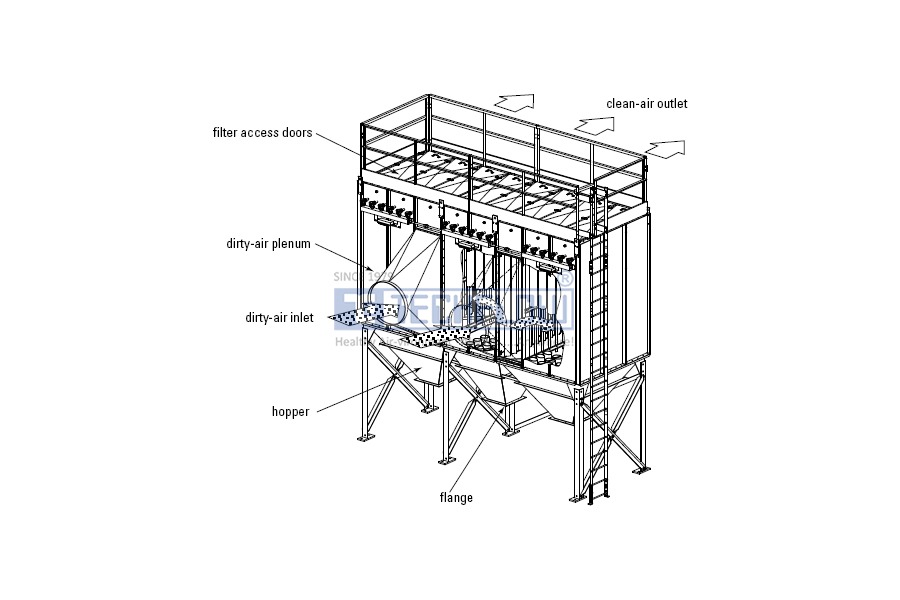

In the Dust collector for ball mill, the degraded air streams through the cartridges. It controls the dust particles, assuring that only cleansed and fresh and dirt-free air stays in the surrounding environment. The Dust collector for ball mill has the convenience of miniature design and low space acquisition. This is the foremost reason why these systems are profoundly used in Shot Blasting, Sand Blasting, Pigments & Chemicals, Mineral Grinding, Ceramics, Polymers, Grinding & Polishing, Food Processing, Abrasive Manufacturing, Pneumatic conveying systems, Spices, Powder coating, Engineering workshops, Cattle Feed & Grain Handling, Welding & Cutting, and many more. Techflow offers a wide variety of Dust collectors for ball mill having a range between 1000 CuM/Hr to 1,00,000 CuM/Hr. These Dust collectors are available with different excesses and alternatives like surface filtration technology, discharge device, and a range of fabrics suitable for distinct applications. |

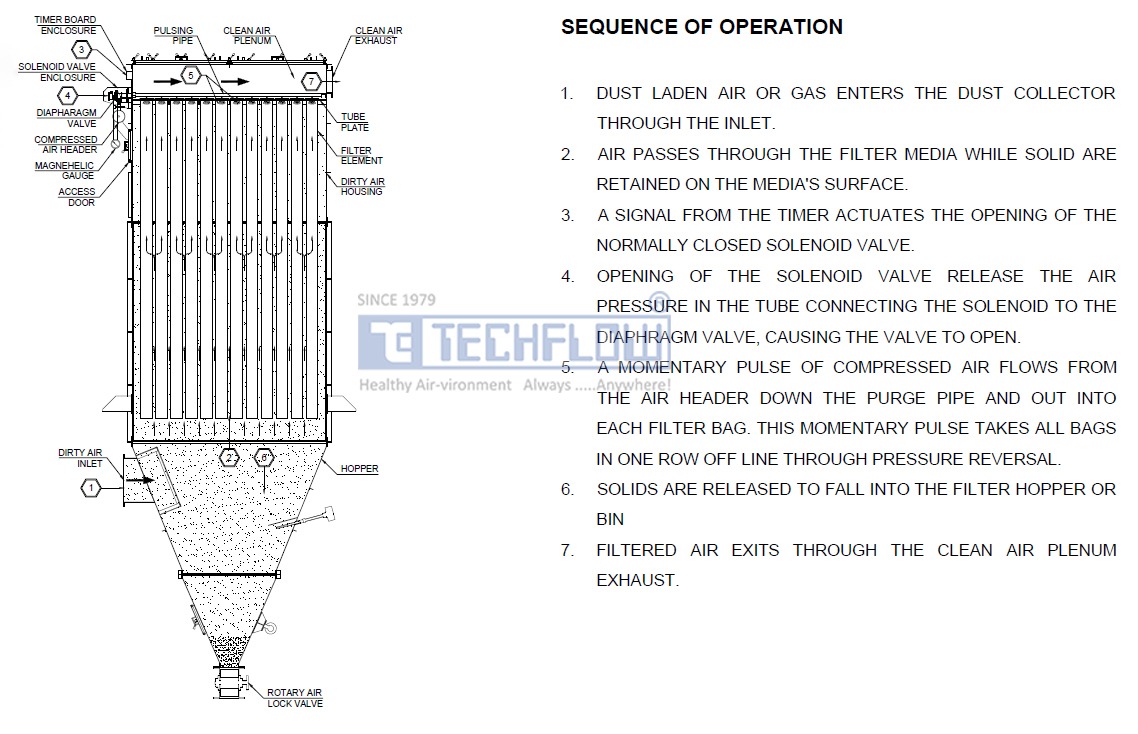

1. OPERATING PRINCIPAL (ONLINE CLEANED)

Dust-packed air arrives in the hopper where weightier particles fall out of the air stream. The more lightweight particles are trapped in the air stream and climb into the filter bags. As the air move through the filter bags, the dust particles are piled on the outside surface of the filter bags, and the cleansed air is drained through the collector. At distinct intervals, jets of consolidated high-pressure air pass through venturis thru the pulse valve and blowpipes, generating a vigorous flow of secondary air, briefly inverting the airflow through the bags. This produces an inner shock wave that crosses down to the end of the bag, causing the bag to pressurize and turn outwards. This allows flipped airflow to dislodge stockpiled dust on the outside of the bag where it slips into a collection hopper. With this procedure of cleaning, airflow through a row of bags is reversed for only a bit of a second, resulting in steady-state airflow states throughout the dust collector. The cleaning procedure is controlled by an easily adapted solid-state timer. A Differential Force gauge permits optimum regulation of the timer. Pulse durations and pulse breaks can be simply and accurately set at the timer to minimize compressed air ingestion.

2. General Function of Dust collector for ball mill

For the clean release of flue gas emissions from pulling out particulate matter & control of SPM level Unit has been developed & manufactured as per combined pre discussions & technical agreement on parameters like Dust loading, Can velocity, Existing & new bag cage sizes Air to cloth ratio, Heaters, Inlets/ outlets, Control system, etc.